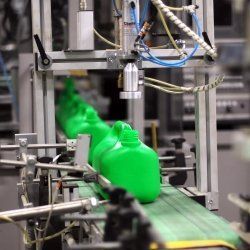

Injection molded plastic products are used in a very wide range of applications, the most common being engineering components and components of other products.

Molten material is, in injection molding, forced into the mold space so filling it. The material cools in the mold, and the product is finished when the mold halves are opened.

A mold can be made up of a number of identical mold cavities, how many depending on the size and weight of the product.

The following text should be entered here:

Injection molded plastic items can be produced in very many materials, the most common materials being PELD, PEHD, PP, PVC, ABS, PA, and TPE.